Medical 3-D printing: Q&A with Dr. Jonathan Morris, Mayo Clinic radiologist

November 03, 2017

by John W. Mitchell, Senior Correspondent

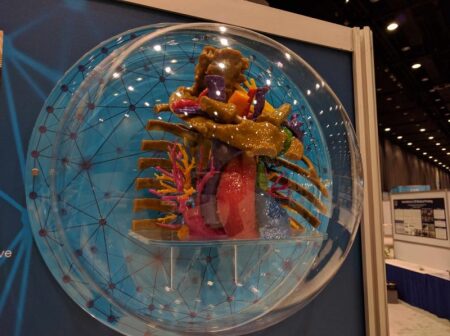

From custom-fitted implants to life-size organ replicas, the ability to 3-D print a CT or MR scan opens up an exciting world of potential in radiology and health care in general.

For Dr. Jonathan Morris, a Mayo Clinic neuroradiologist specializing in spine procedures, the brave new world of medical 3-D printing is practically business as usual. That’s because he and fellow radiologist, Dr. Jane Matsumoto, co-direct an in-house 3-D printing lab at Mayo and are at the forefront of discovering new ways 3-D printing is poised to improve patient care.

HealthCare Business News spoke to Morris about how the utilization of 3-D printing grew at Mayo Clinic in Rochester, Minn., what types of cases benefit the most from the technology, what hurdles stand in the way of greater utilization across the industry and why he believes medical 3-D printing belongs under the umbrella of radiology.

HCB News: What are some ways that 3-D printing has benefited Mayo Clinic?

Jonathan Morris: There are a lot of things in medicine and surgery where we have to remove pieces of the body and put other things in. A lot of that just comes into simple sizing. ‘How big is the piece I need?’

With 3-D printing, most of it starts with either a CT or MR scan. We upload that into medical CAD software and then we color code the things we want to print through a process called segmentation. After that we can put them into SDL file format which we export to the printers. One CT of the entire spine, for example, might be 5,000 images, so to be able to get all that through a machine into a printer requires significant computing power.

We started doing patient-specific, pre-surgical simulations at Mayo with mandibular tumors where we plan all the cuts ahead of time and we actually print cutting guides that are screwed onto the patient’s bone. Doing this, you decrease the time in the OR, improve the outcome of the patient and decrease the cost, which is the holy grail of medicine.

Then, one of our world-class vascular surgeons made a similar discovery. He works with companies to make stents, but sometimes there is not a solution on the market so we started printing patient-specific aortas that had an aneurysm and developing custom solutions for them.

They also started practicing difficult stent placements. We take the CT scan and turn it into a three-dimensional model and then they would do the actual interventional procedure on the model, which is an exact replication of the patient’s anatomy. In doing so, we moved into patient simulation.

With 3-D printing, they can train their fellows, their residents and medical trainees on how to do actual procedures without directly involving the patient. We have so many residents and fellows and we have to educate a large number of people, so the models are part of that.

HCB News: How did Mayo Clinic’s journey into 3-D printing begin?

JM: We had a set of conjoined twins that came to Mayo 11 years ago. The surgeons asked us if we could make a 3-D model of their liver because their anatomy was complex and they had to choose where to cut on the liver. That choice is traditionally made through CT and MR scans, which are two-dimensional imaging, but sometimes it’s difficult conceptually to make that 3-D object life-size in your mind.

When we show imaging studies the object is as big as the screen is. If the screen is an iPhone, it’s the size of an iPhone. If the screen is 40 feet at a big national conference, the size of the image is 40 feet. It’s difficult to provide realistic size in your mind from two-dimensional objects.

We said we could probably make a 3-D-printed liver, but we didn’t have a 3-D printer at the time. So, we used one at the local community college. Dr. Matsumoto was heavily involved with the conjoined twins imaging. The surgeons would say, ‘we needed a way to get what’s in her mind out into the world,’ because she understood the anatomy in a way no one else did. 3-D printing was the way.

We’ve done about 500 or maybe 600 models this year for preoperative and surgical planning. From spines, we went into oncology with tumor resection. One of the neurosurgeons will have a big tumor in the spine with blood vessels around it, so we make a model that has blood vessels and the tumor. Then, they can plan the surgery or evaluate different approaches they hadn’t considered before they had models. Once we started doing tumors, we never looked back.

After the local community college, we started using 3-D printers from the Department of Engineering at Mayo. Mayo has 60 engineers embedded in the hospital system. They had some 3-D printers and we used theirs early on with the spine. Then it became so useful for the surgeons that we started developing in-hospital printing capabilities, which was very novel. There was only one other place, Walter Reed National Military Medical Center, that was doing anything even remotely close.

HCB News: What types of surgeons are utilizing 3-D printing the most?

JM: There are so many different types of surgeons at Mayo operating in so many different fields that they are really driving our practice. They would come and say, ‘I want to take out a tumor from this place, but I want to do it through a little keyhole incision. Can you make me a model?’

From the very first model through today, 3-D printing has aided pre-surgical planning. When you have a 3-D model that has maybe the bone and the tumor and the blood vessels and you might have an orthopedic surgeon, a GI surgeon, a GYN surgeon, all those people can talk about the case using the model in real life and real size.

Eventually, the spine surgeons saw the models. I do complex pediatric scoliosis and we started creating a lot of spines for more complex patients. When we started doing that they started realizing that not only is it good for the surgeon in preoperative planning, but they’re really helpful to patients because now the surgeon can use models as a vehicle to discuss what’s wrong with them or their child.

HCB News: What are the challenges in establishing a program like this?

JM: These printers all have to be vented. They’re working with polymers so they all have to be vented to the outside. Hospital infrastructure is not really set up for these kinds of systems, so we worked with specialists to develop a manufacturing capability inside the hospital.

Now we’re into thousands of square feet for 3-D production. We don’t just do it for Rochester. We do it for the entire Mayo enterprise. We’ve started printing programs at both the Jacksonville [Fla.] and Scottsdale [Ariz.] satellite areas, but we’re the main site. Instead of 3-D printers popping up everywhere, we decided to centralize things and provide support for the other areas.

By getting into the 3-D printing medical space early on we also designed the quality programs to ensure images that get transferred don’t get corrupted. When you go to the printer you need to be sure it does what it says it‘s going to do and prints things that are the correct size. By working with the Society of Manufacturing in Engineering and groups that use 3-D printing in other industries we’ve created all kinds of quality standards that ensure the printers are working the way they should.

An error in surgery is a huge deal, and if we send something down to the OR that’s the wrong size, it can lead to a medical error. So, from the very beginning of our lab, we have been focused on quality and safety.

We don’t get the 3-D models reimbursed right now, but Mayo’s overriding principle is the needs of the patient come first. We were doing the printing pro bono at first, and as we kept showing that this improves care, we went for more resources and committed to offering this service.

HCB News: What are the next steps for medical 3-D printing?

JM: It still takes talented surgeons to use this technology. 3-D printing is just another tool at their disposal to be innovative, do procedures that they probably didn’t think they could do less invasively and have better outcomes.

We’ve worked with the FDA for the past three years to help guide regulations. These things are starting to be used to make medical decisions, so there is going to be some regulation.

Eventually, we’ll try and develop reimbursement codes. The Japanese health system reimburses for medical 3-D models for oncological care, and some places in England are starting to consider it. So, it’s going to happen. For the surgeons, it’s such a no-brainer thing to do.

Also, there are a lot of bottlenecks for 3-D printing. The segmentation software is not user-friendly from a physician standpoint because the software was designed for engineers to use. An adult bone is just a few clicks, but if we want an adult bone with arteries, veins, kidneys, tumor, that can take four hours to segment. So, I think the next frontier will involve improving the efficiency of 3-D printing in complex oncology cases and heart surgery.

In the world of bioprinting, the next frontier is to begin to be able to print scaffolds that you put inside the body where bone will actually grow along the scaffold. Those are already out of large animal trials and moving into human trials. There is a skin printing trial that is ongoing. So, in the bioprinting world, to be able to print bone, cartilage or at least scaffolds where these will grow is a big deal.

We strongly believe that 3-D should be under the umbrella of radiology. The radiologists know the images the best, know the anatomy the best and know where the tumors are the best. We should be the ones doing the segmentation. All specialties come through radiology. If you get 3-D printing popping up like mushrooms in every department with no quality check, then there are all these printers operating with no oversight. Then, eventually, there will be a medical error.

For Dr. Jonathan Morris, a Mayo Clinic neuroradiologist specializing in spine procedures, the brave new world of medical 3-D printing is practically business as usual. That’s because he and fellow radiologist, Dr. Jane Matsumoto, co-direct an in-house 3-D printing lab at Mayo and are at the forefront of discovering new ways 3-D printing is poised to improve patient care.

HealthCare Business News spoke to Morris about how the utilization of 3-D printing grew at Mayo Clinic in Rochester, Minn., what types of cases benefit the most from the technology, what hurdles stand in the way of greater utilization across the industry and why he believes medical 3-D printing belongs under the umbrella of radiology.

HCB News: What are some ways that 3-D printing has benefited Mayo Clinic?

Jonathan Morris: There are a lot of things in medicine and surgery where we have to remove pieces of the body and put other things in. A lot of that just comes into simple sizing. ‘How big is the piece I need?’

With 3-D printing, most of it starts with either a CT or MR scan. We upload that into medical CAD software and then we color code the things we want to print through a process called segmentation. After that we can put them into SDL file format which we export to the printers. One CT of the entire spine, for example, might be 5,000 images, so to be able to get all that through a machine into a printer requires significant computing power.

We started doing patient-specific, pre-surgical simulations at Mayo with mandibular tumors where we plan all the cuts ahead of time and we actually print cutting guides that are screwed onto the patient’s bone. Doing this, you decrease the time in the OR, improve the outcome of the patient and decrease the cost, which is the holy grail of medicine.

Then, one of our world-class vascular surgeons made a similar discovery. He works with companies to make stents, but sometimes there is not a solution on the market so we started printing patient-specific aortas that had an aneurysm and developing custom solutions for them.

They also started practicing difficult stent placements. We take the CT scan and turn it into a three-dimensional model and then they would do the actual interventional procedure on the model, which is an exact replication of the patient’s anatomy. In doing so, we moved into patient simulation.

With 3-D printing, they can train their fellows, their residents and medical trainees on how to do actual procedures without directly involving the patient. We have so many residents and fellows and we have to educate a large number of people, so the models are part of that.

HCB News: How did Mayo Clinic’s journey into 3-D printing begin?

JM: We had a set of conjoined twins that came to Mayo 11 years ago. The surgeons asked us if we could make a 3-D model of their liver because their anatomy was complex and they had to choose where to cut on the liver. That choice is traditionally made through CT and MR scans, which are two-dimensional imaging, but sometimes it’s difficult conceptually to make that 3-D object life-size in your mind.

When we show imaging studies the object is as big as the screen is. If the screen is an iPhone, it’s the size of an iPhone. If the screen is 40 feet at a big national conference, the size of the image is 40 feet. It’s difficult to provide realistic size in your mind from two-dimensional objects.

We said we could probably make a 3-D-printed liver, but we didn’t have a 3-D printer at the time. So, we used one at the local community college. Dr. Matsumoto was heavily involved with the conjoined twins imaging. The surgeons would say, ‘we needed a way to get what’s in her mind out into the world,’ because she understood the anatomy in a way no one else did. 3-D printing was the way.

We’ve done about 500 or maybe 600 models this year for preoperative and surgical planning. From spines, we went into oncology with tumor resection. One of the neurosurgeons will have a big tumor in the spine with blood vessels around it, so we make a model that has blood vessels and the tumor. Then, they can plan the surgery or evaluate different approaches they hadn’t considered before they had models. Once we started doing tumors, we never looked back.

After the local community college, we started using 3-D printers from the Department of Engineering at Mayo. Mayo has 60 engineers embedded in the hospital system. They had some 3-D printers and we used theirs early on with the spine. Then it became so useful for the surgeons that we started developing in-hospital printing capabilities, which was very novel. There was only one other place, Walter Reed National Military Medical Center, that was doing anything even remotely close.

HCB News: What types of surgeons are utilizing 3-D printing the most?

JM: There are so many different types of surgeons at Mayo operating in so many different fields that they are really driving our practice. They would come and say, ‘I want to take out a tumor from this place, but I want to do it through a little keyhole incision. Can you make me a model?’

From the very first model through today, 3-D printing has aided pre-surgical planning. When you have a 3-D model that has maybe the bone and the tumor and the blood vessels and you might have an orthopedic surgeon, a GI surgeon, a GYN surgeon, all those people can talk about the case using the model in real life and real size.

Eventually, the spine surgeons saw the models. I do complex pediatric scoliosis and we started creating a lot of spines for more complex patients. When we started doing that they started realizing that not only is it good for the surgeon in preoperative planning, but they’re really helpful to patients because now the surgeon can use models as a vehicle to discuss what’s wrong with them or their child.

HCB News: What are the challenges in establishing a program like this?

JM: These printers all have to be vented. They’re working with polymers so they all have to be vented to the outside. Hospital infrastructure is not really set up for these kinds of systems, so we worked with specialists to develop a manufacturing capability inside the hospital.

Now we’re into thousands of square feet for 3-D production. We don’t just do it for Rochester. We do it for the entire Mayo enterprise. We’ve started printing programs at both the Jacksonville [Fla.] and Scottsdale [Ariz.] satellite areas, but we’re the main site. Instead of 3-D printers popping up everywhere, we decided to centralize things and provide support for the other areas.

By getting into the 3-D printing medical space early on we also designed the quality programs to ensure images that get transferred don’t get corrupted. When you go to the printer you need to be sure it does what it says it‘s going to do and prints things that are the correct size. By working with the Society of Manufacturing in Engineering and groups that use 3-D printing in other industries we’ve created all kinds of quality standards that ensure the printers are working the way they should.

An error in surgery is a huge deal, and if we send something down to the OR that’s the wrong size, it can lead to a medical error. So, from the very beginning of our lab, we have been focused on quality and safety.

We don’t get the 3-D models reimbursed right now, but Mayo’s overriding principle is the needs of the patient come first. We were doing the printing pro bono at first, and as we kept showing that this improves care, we went for more resources and committed to offering this service.

HCB News: What are the next steps for medical 3-D printing?

JM: It still takes talented surgeons to use this technology. 3-D printing is just another tool at their disposal to be innovative, do procedures that they probably didn’t think they could do less invasively and have better outcomes.

We’ve worked with the FDA for the past three years to help guide regulations. These things are starting to be used to make medical decisions, so there is going to be some regulation.

Eventually, we’ll try and develop reimbursement codes. The Japanese health system reimburses for medical 3-D models for oncological care, and some places in England are starting to consider it. So, it’s going to happen. For the surgeons, it’s such a no-brainer thing to do.

Also, there are a lot of bottlenecks for 3-D printing. The segmentation software is not user-friendly from a physician standpoint because the software was designed for engineers to use. An adult bone is just a few clicks, but if we want an adult bone with arteries, veins, kidneys, tumor, that can take four hours to segment. So, I think the next frontier will involve improving the efficiency of 3-D printing in complex oncology cases and heart surgery.

In the world of bioprinting, the next frontier is to begin to be able to print scaffolds that you put inside the body where bone will actually grow along the scaffold. Those are already out of large animal trials and moving into human trials. There is a skin printing trial that is ongoing. So, in the bioprinting world, to be able to print bone, cartilage or at least scaffolds where these will grow is a big deal.

We strongly believe that 3-D should be under the umbrella of radiology. The radiologists know the images the best, know the anatomy the best and know where the tumors are the best. We should be the ones doing the segmentation. All specialties come through radiology. If you get 3-D printing popping up like mushrooms in every department with no quality check, then there are all these printers operating with no oversight. Then, eventually, there will be a medical error.